Choosing the Best Construction Method: Construction Manager At-Risk vs Design-Build

January 23, 2026

January 23, 2026

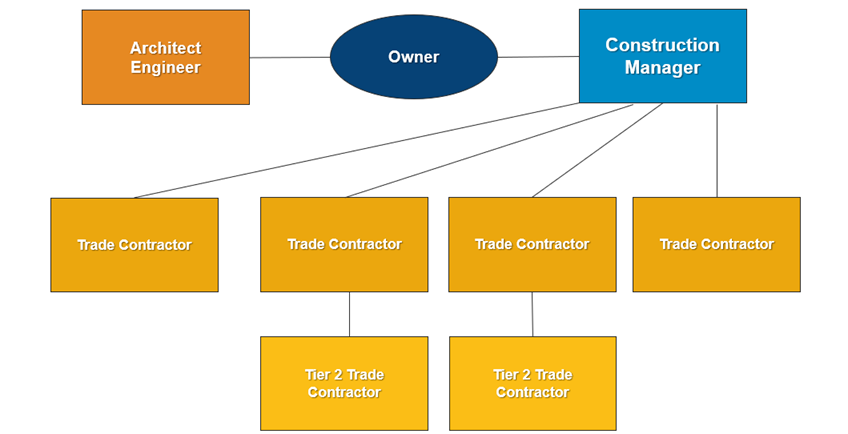

Construction management at risk, or CMAR, is a construction delivery method known for its two-contract approach between the owner, contractor, and architect/engineer.

The public owner holds separate contracts for the project’s design and construction.

Owners gravitate to the CMAR delivery method for several reasons. One key advantage is that the construction manager is on-site throughout the project, ensuring quality construction and providing valuable input during the design phase.

Selected during preconstruction, the construction manager can assist the team during the design phase to provide input on estimating, constructability, scheduling, and required value engineering.

Given the inherent design of construction management at risk procurement, there are a few downsides that are often overlooked and can lead to headaches for the owner, including:

Separate contracts for design and construction introduce distinct risks for the owner. Firstly, the design contract involves the architect’s standard of care, which refers to the level of skill, competence, and diligence that a reasonably prudent architect would exercise under similar circumstances.

While architects are responsible for providing designs that meet industry standards, they are not liable for unforeseen construction issues, material availability, or contractor errors.

On the other hand, the construction contract is governed by the Spearin Doctrine, which holds that contractors are not liable for design flaws in owner-accepted designs. This doctrine holds that any gaps between the design and construction phases can lead to change orders, escalating project costs, or reduced project scope, all of which pose significant risks to the owner.

The owner may think they are on one team with their architect/engineer and construction manager. However, they are not.

Contractually, the architect/engineer and construction manager are separate entities employed by the owner with no incentive to collaborate. Often, the result is finger-pointing, with the Owner left holding the liability or legal challenges.

CM at risk creates opportunities for public owners to be hit with costly change orders for plans/specifications gaps, unforeseen site conditions, or design adjustments.

More often than not, the price you commit to is not the price you pay.

Change orders naturally create delays due to the need for review and approval. Every question or issue can cause delays. Issues can take days or weeks to resolve, impacting the schedule.

In fact, the Design Build Institute of America reported that Design-Build construction is 61% faster than the CMAR delivery method.

Because the CM at risk contract separates the architect and construction manager, the separate teams with no contractual obligation to one another, they don’t have an incentive to collaborate. So, when budgets are tight, design scopes are value-engineered reactively, leading to design cuts that may disappoint the owner.

Design-build construction keeps all parties involved on the same team. Instead of holding multiple contracts, the owner contracts directly with a single design-builder, who is solely responsible for the planning, design, and construction of the project.

The design-build contract outlines the agreement between the owner and the design-builder to provide design and construction, with a focus on cost, delivery speed, and a quality outcome that meets the owner’s objectives.

Owners increasingly choose design-build because it provides a single point of responsibility, streamlining communication and decision-making. Design-build pros are that the approach delivers projects faster and saves costs by eliminating separate bidding phases and parallel schedules.

The collaborative nature of design-build encourages innovative solutions and efficient designs while improving risk management. Quality is enhanced as a single team oversees both design and construction. Additionally, design-build allows for flexibility during construction and simplifies design-build project management for owners.

Related Reading: 10 Reasons Why the Design-Build Delivery Method Works

“The most significant consideration in our selection decision was a single point of contact with one contract. The board and I did not want any buck-passing or finger-pointing. With design-build, the buck started and ended with the design-builder. For our situation, time was critical, so this delivery method with sole accountability for both design and construction was right for our project.” – Jordan Sinz, Former District Administrator | Wisconsin Heights School District

There is a common misconception that because the final construction documents aren’t completed before selection, the project is somehow less defined or riskier.

While in reality, design-build construction allows the owner to select a team based on qualifications, approach, and preliminary concepts—not 100% finalized drawings. This method actually gives the owner greater flexibility and decision-making power.

There is a common misconception that design-build lacks checks and balances because the architect and builder are on the same team, unlike CMAR, where roles are separated.

While in reality, design-build still incorporates accountability through shared goals, transparency, and continuous collaboration. Because designers and builders work together from the start, communication is more direct, issues are addressed earlier, and the team is collectively incentivized to solve challenges efficiently and in the owner’s best interest.

There is a common misconception that design-build results in higher upfront costs compared to other delivery methods.

While in reality, design-build uses a design-to-target budget approach that aligns design decisions with cost expectations from the beginning. Early collaboration and transparency with open-book pricing help establish known project costs sooner, reducing cost overruns and eliminating change orders.

There is a common misconception that design-build limits owner involvement once the project team is selected.

While in reality, design-build places the owner at the center of the process by encouraging active participation throughout design and construction. Through intentional listening and collaboration, the team develops solutions guided by the owner’s priorities, ensuring project goals are clearly defined, understood, and achieved.

Related Reading: Debunking Common Design-Build Myths: Separating Fact from Fiction

Choosing the right construction approach is one of the most important decisions an owner must make when beginning a construction or renovation project.

Owners must understand not only their delivery method options but also the decision’s impact. Each method varies on when parties become engaged, how contracted parties interact, and how changes and modifications are handled and impact the overall project. The decision is crucial to a project’s success as it can significantly impact cost, schedule, quality, and risk management.

Construction delivery methods allocate project risks differently among stakeholders, with some methods helping to mitigate risks related to schedule delays and cost overruns.

Before beginning a project, weigh the pros and cons and examine each model critically to ensure your project has the greatest likelihood of success. Most importantly, consider the following factors and how they could impact the success of your project:

Understanding the inherent differences between CMAR vs design-build delivery models is crucial. Additionally, there is a traditional model called design-bid-build with various pros and cons to consider.

Before starting any project, whether large or small, carefully consider your goals, priorities, and expectations to determine which method best aligns with your goals. While researching, look into the history of the procurement methods to really understand its value. Read more about the history of construction here.

Our team of architects, engineers, and project managers is ready to help with your next project. Contact us today for a collaborative, team-oriented approach to ensure the success of your next new construction or renovation project.

Performance Services delivers on time, every time.