From Aging Infrastructure to Modern Efficiency

The Boonville R-1 School District is home to approximately 1,600 students across five schools. With a strong focus on creating an environment where students can thrive, the district recognized the need to address aging infrastructure and enhance energy efficiency.

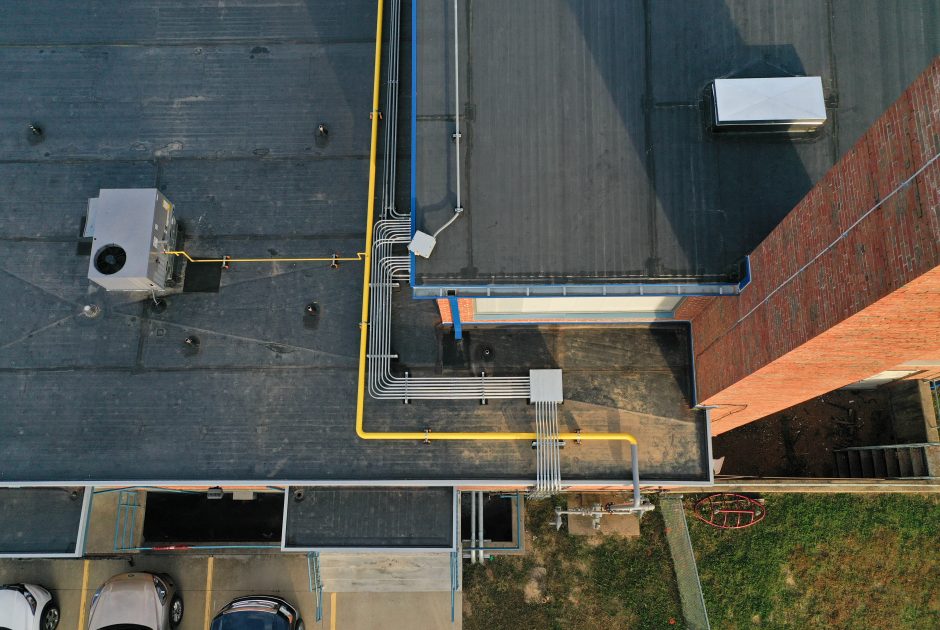

In 2020, the district embarked on a comprehensive energy savings initiative to modernize its facilities. The initial focus was on Laura Speed Elliott Middle School, where the existing HVAC system was not only outdated but also undersized, leading to performance inefficiencies and increased operational costs. Recognizing the need for a more efficient system, the district prioritized upgrading the HVAC equipment to ensure a comfortable and conducive learning environment.

Building on the success of this initial phase, the district expanded its efforts to other schools after completing a district-wide facilities assessment and long-range planning study with Performance Services:

- Boonville High School: Transitioned to energy-efficient LED lighting both inside and outside, enhancing visibility and reducing energy consumption.

- Football Stadium: Replaced the aging grandstands with new aluminum seating, improving accessibility and safety.

- Laura Speed Elliott Middle School: Replaced the cooling tower and remodeled the weight room, which included new HVAC installations, updated flooring, ceilings, lighting, reconfigured stairways, and new doors. Completed a new secure entrance.

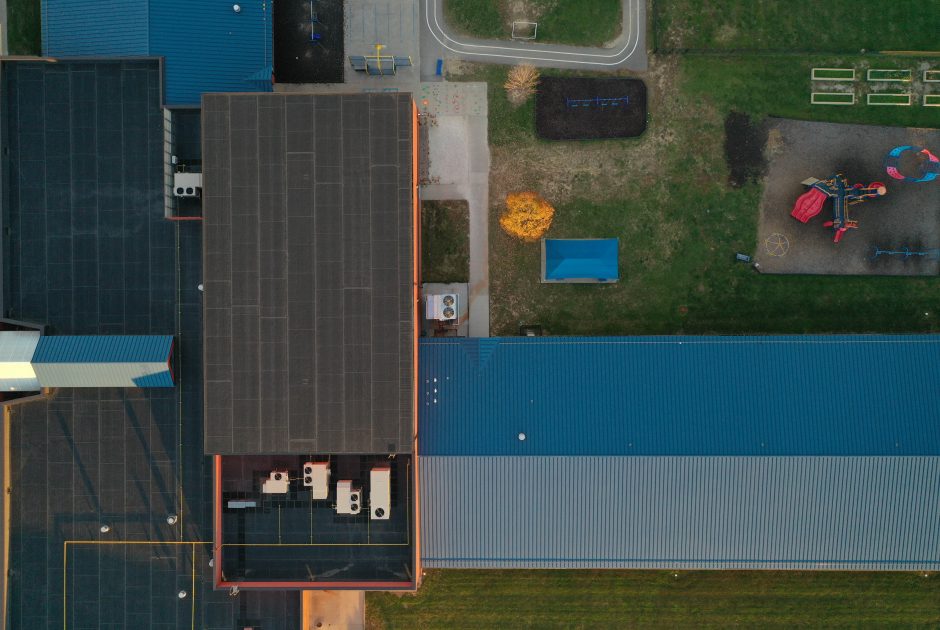

- David Barton Elementary: Undertook significant infrastructure improvements, including roof replacement, electrical panel upgrades, a new fire alarm system, and the addition of a secure entryway to increase student safety. Remodeled interior classrooms, offices and restrooms, to bring the old building up to modern standards and ADA code compliance.

- Hannah Cole Elementary: Installed new natural gas-fired dedicated outdoor air systems, installed new boilers and cooling tower, recommissioned ground source heat pump units, and upgraded temperature controls.

- Boonslick Technical Education Center (BTEC): The shop classrooms were enhanced with LED lighting, new ceilings, reconfigured spaces, and upgraded ventilation and exhaust systems, including new fume extraction units in the auto shop and welding stations, ensuring a safer and more efficient learning environment for technical education students.

These comprehensive improvements not only modernized the district’s facilities but also led to substantial energy and operational savings, with annual energy and operational/capital cost avoidance savings of $301,588 across all phases. Additionally, the district secured $71,360 in rebates, further supporting its commitment to fiscal responsibility and environmental stewardship.

Through these initiatives, the Boonville R-1 School District has demonstrated a steadfast commitment to enhancing the educational experience, ensuring that students and staff benefit from safe, efficient, and modern facilities that support learning and growth.

Upgrades are Saving School District Money

By Laura Wax – Boonville Daily News | December 24, 2025

“The competed projects have brought in thousands in annual savings. Phase 1, completed in 2021, brought in $29,677 in energy savings; Phase 2, completed in 2023 saved $54,000 in operational savings; Phase 3, completed in 2022, saved $197,594 in operational savings, and Phase 4, completed in 2023 saved $20,317 in operational savings. The district has also seen an impact on utilities. The district experienced a 2,021,860 kWh, or 27.3%, reduction in electric consumption since 2021, PSI reported.”